Monitor the condition of your machinery and prevent damage by regularly testing and checking lubricants!

More reliable engine components. Reduced costs.

Our technical service department conducts an analysis process, based on monitoring the condition of engine components, carried out by studying lubricant samples.

The reason why these analyses are performed is because lubricants interacting with engine components carry with them traces of the correct or incorrect operation of the operating parts.

By thus detecting the traces of such signals, our technical service department is able to anticipate possible failures and malfunctions, thus avoiding costly repairs or the accumulation of damage.

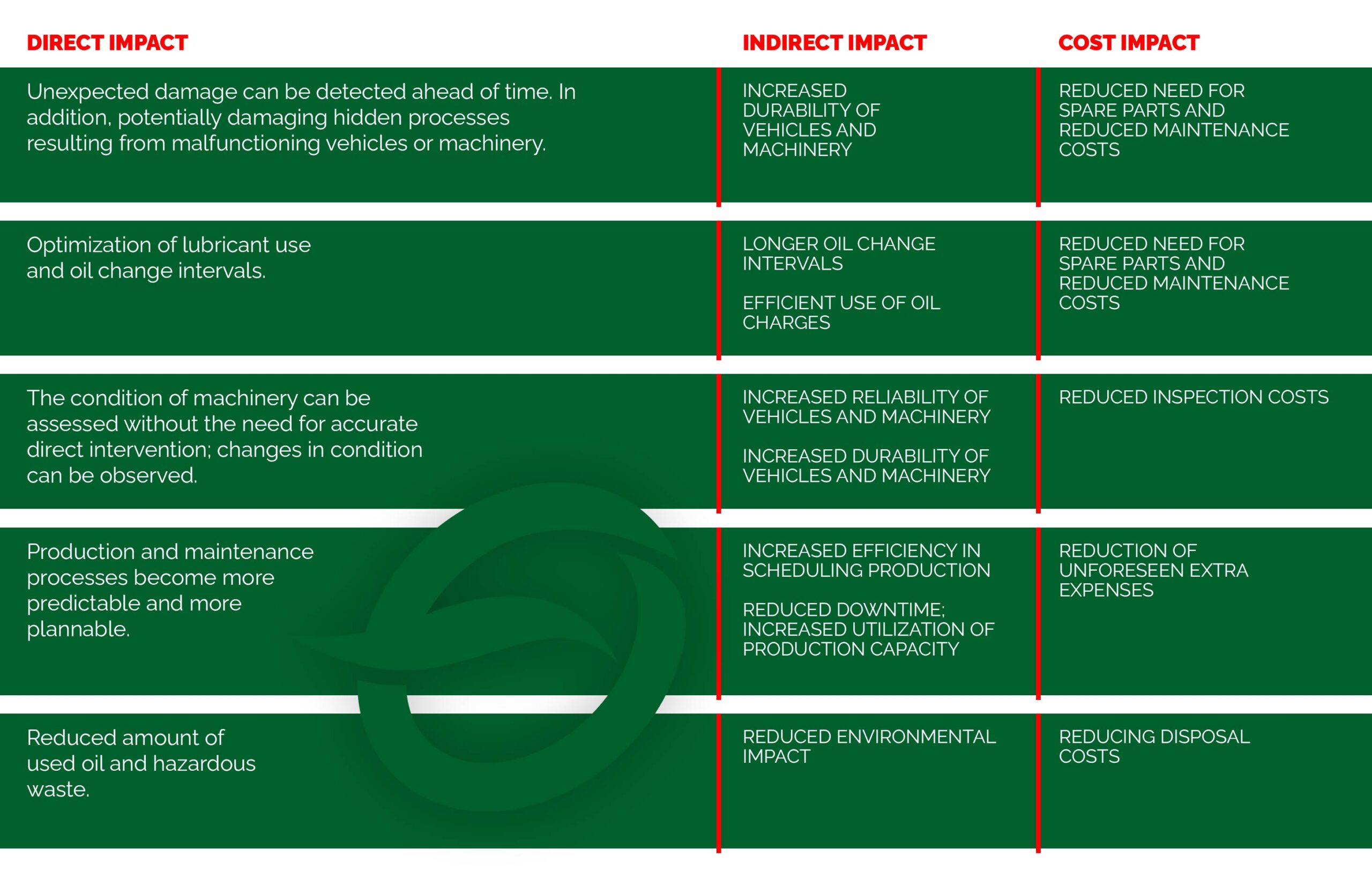

Some examples of intervention:

- Early detection of hidden processes that may cause damage;

- Reduction or elimination of machinery downtime;

- Reduced maintenance costs;

- More accurate and more easily planned maintenance;

- Optimization of lubricant replacement intervals;

- Increased reliability of vehicles and machinery.

We thoroughly analyze and carefully interpret the analysis information hidden in a drop of oil and use it to optimize maintenance operations.

Some of our tests analyze both the values of physical and chemical parameters of lubricants and the intensity of changes, types and amounts of contaminants as well as metal residues in lubricants.

In addition, we rely on the information obtained about the correct or incorrect operation of machinery, correct or incorrect selection of lubricants, and better management of those already in use.